FAQ

Have Questions?

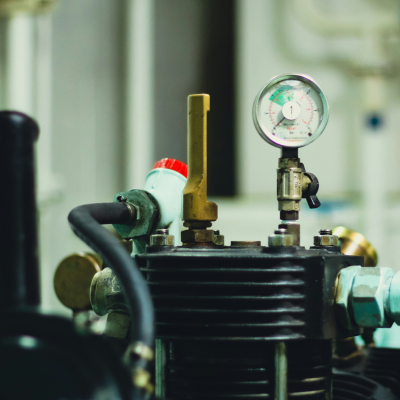

Compressor Service – Frequently Asked Questions

The recurring maintenance intervals depend on the actual operating hours and time. This means that a compressor that does not reach its operating hours within 6 or 12 months or until the next recurring maintenance, it still needs a service as various wearing parts and filters are subject to an ageing process. With special consideration of the operational safety and the guarantee of a trouble-free operation, it is recommended to observe the specified maintenance intervals depending on the type of plant. Minimum interval 1 x per year.

Depending on the filter element and function, the filter elements should be changed every 6 or at least every 12 months.

In order to ensure a continuous supply of high-quality compressed air and to reduce energy costs, filter elements must be replaced regularly.

The oil change is usually carried out in connection with recurring maintenance. Mineral compressor oil should be changed every 4000 operating hours. Synthetic compressor oils can usually be operated twice as long. However, depending on the installation and suction conditions, the oil change intervals may vary. In case of doubt it is recommended to have the condition tested in the laboratory by means of an oil analysis (oil check).

In principle, a compressor oil approved by the plant manufacturer must be used. The compressor oil is of the greatest importance in the compressor (for oil-lubricated screw compressors). The oil must cool, compress and lubricate. However, it also needs the property to be separable again afterwards. Depending on the application of the system, mineral oils can also be used as synthetic or food oils.

Ecologically, it is of course always sensible to switch off unnecessary energy consumers. However, with a refrigeration dryer, it should always be remembered that the dryer capacity is not immediately available after the dryer has been switched on. The refrigerant dryer needs a pre-run to cool down its system. This time varies from dryer to dryer, so as a precaution the dryer should be switched on half an hour before the compressor starts.

If it cannot be ensured that the dryer is started in time, the dryer should remain switched on permanently, because the costs and energy required to remove the condensate from the piping system far exceed the possible savings by switching off the refrigeration dryer.

Request a Quote Today

Reach Us

Location:

No. 3/75/76AB, K.Vadamadurai, Mariyamman Kovil Street, Coimbatore – 641017

Email:

aircruiserie19@gmail.com

Phone:

090036 05662